In this post we ask:

- How Long Does Polyurea Coating Last?

- How Does Polyurea compare to Epoxy?

- What are the latest Polyurea advancements?

What is polyurea?

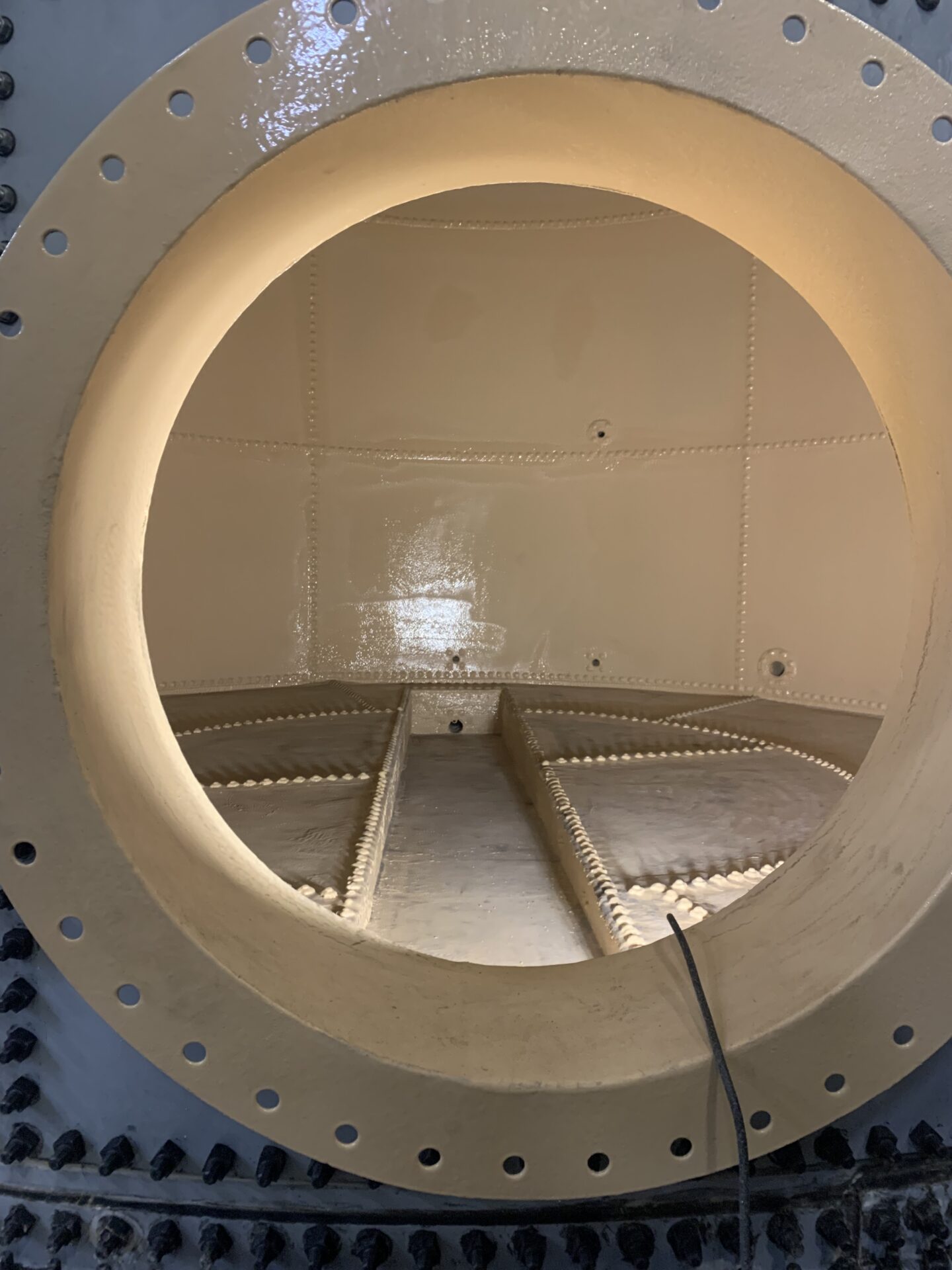

We all know Industrial construction jobs demand high-quality materials which produce long-lasting results. One of the best products on the market today is a polyurea liner, also known as polyurea coating. Polyurea is easy to clean and maintain, has excellent chemical resistance and waterproofing ability, and is rapid curing. All while offering an environmentally friendly option that will provide long-lasting results.

How long does polyurea last?

A properly applied polyurea lining can last for decades. This is one of the reasons why polyurea has become the standard for a wide array of construction applications and the reason why we rely so heavily on it at Southern Industrial Linings. Barring extreme physical damage from a harsh impact, polyurea lining can easily last 30 or 40 years. Compared to other common materials such as epoxy, polyurea is the superior choice.

The benefits noted above are not the only reason to choose a polyurea!

Because polyurea provides both nonskid coating and abrasion resistance, it’s excellent for heavily trafficked surfaces. You might even have it in your truck bed or RV! However, its chemical resistance is why it’s such a useful product for wastewater applications. Wastewater facilities deal with some of the harshest conditions possible. A polyurea treatment keeps the structure safe from corrosion and degradation.

Polyuera vs Epoxy

Many epoxy-based products promise long-lasting protection against corrosion in wastewater applications. However, many of these epoxy coatings fail to handle the harsh environments that wastewater creates. Epoxies are susceptible to degradation by hydrogen sulfide gas. Bacteria release this gas in wastewater over time. A study of a wastewater plant in Europe revealed damage to epoxy-treated pipes after just two years!

Contrast those results with those of studies that focus on polyurea-treated concrete. The polyurea coating actually makes the structure stronger, allowing it to resist stress better. This is very useful for ongoing construction projects where lots of vibration occurs. A properly applied epoxy coating could be damaged while construction continues. Polyurea products, on the other hand, show remarkable resistance and make the materials they are applied to even better.

New Polyurea Products

Polyurea coating technology continues to advance. There are new formulations in development that use epoxy as a base but add polyurea microcapsules to make the final product superior. What makes these new formulations so special is that by adding polyurea to the mix, the final product is able to heal itself after being damaged. A study applied regular epoxy coatings and a polyurea-enhanced coating to identical surfaces and then put them through various stress tests.

The results of the experiment were pretty impressive. The coatings that included polyurea improved the durability of the surfaces they were applied, confirming the studies previously mentioned. However, when even more polyurea was added (up to 5% of the total weight), the final product could self-heal up to 61% of the damage done in the stress tests. These results help explain why polyurea treatments last longer than epoxy-based coatings. (Corrosionpedia)

Give us a shout if you have a project! Contact us here

For more information on “Poly”, be sure and check out this article from the good folks at Corrosionpedia.